Product description

FRAMES (not insulated)

The frames are made from glue-laminated spruce beams. The frame consists of the bottom frame (100 x 140 mm), columns (140 x 140 mm), top frame (140 x 200 mm). They are the perfect material for exceptionally stable and high-quality timber

construction.

The roof panels are built with double rafters construction and covered with 18 x 145 mm finishing boards. Viking cube buildings’ roofs are 2.9 m high and 1.310 (2.29%) slope. We use MIDA SELF KSK for the roof covering, its self-adhesive elastomeric bitumen membrane covering the entire surface. The rolled roofing installation is a quick, simple, and safe way to cover all Cube roof. All you must do is unroll, attach with nails, remove the protective film, and press. The door is made of 146 x 28 mm floorboards.

FRAME DESIGN. Self-standing and modular system cube specifications

- TOP FRAME 140 x 200 mm

- COLUMNS 140 x 140 mm

- BOTTOM FRAME 100 x 140 mm

- FLOOR 146 x 28 mm floorboards

AVAILABLE CUBE FRAME SIZES:

- CUBE FRAME 2 x 2 m. Frame 2286 x 2286 (4 m2) from spruce: floor, columns, and roof.

- CUBE FRAME 2 x 3 m. Frame 2286 x 3286 (6 m2) from spruce: floor, columns, and roof.

- CUBE FRAME 2 x 4 m. Frame 2286 x 4286 (8 m2) from spruce: floor, columns, and roof.

- CUBE FRAME 3 x 3 m. Frame 3286 x 3286 (9 m2) from spruce: floor, columns, and roof.

- CUBE FRAME 3 x 4 m. Frame 3286 x 4286 (12 m2) from spruce: floor, columns, and roof.

Several cubes can be interconnected.

| Timber | Spruce |

| Room | 1 |

| Total height | 2900mm |

| Floor thickness | 28mm |

| Garden cube frame from spruce: floor and roof panels, 4 columns. |

| The frames are made from glue laminated spruce beams. |

| Frame consists of bottom frame (100 x 140 mm), columns (140 x 140 mm), top frame (140 x 200 mm). |

| The floor is made of 146 x 28 mm floor board. |

| Roof panels with self-adhesive bitumen membrane. |

| Roof panels with self-adhesive bitumen membrane. |

Viking Modular Garden Cubes

Size of the cargo (L x W x H): not assembled products on pallets ready for transportation:

- CUBE FRAME 2 x 2 m: 2.60 x 1.20 x 2.60 m.

- CUBE FRAME 2 x 3 m: 3.40 x 1.20 x 2.60 m.

- CUBE FRAME 2 x 4 m: 4.40 x 1.20 x 2.60 m.

- CUBE FRAME 3 x 3 m: 3.40 x 1.20 x 2.60 m.

- CUBE FRAME 3 x 4 m: 4.40 x 1.20 x 2.60 m.

AUTOMATIC MACHINE SPRAY TECHNOLOGY

Benefits

One of the main and most obvious benefits of using a paint machine is the speed and flexibility at which we can suggest our painting service for all of our products. A spray paint machine can get the work done faster and more consistently than manually painting. While the machine works faster, it improves quality too – sprayers produce an even coat of paint, leaving a high-quality finish.

With our painting service from now, we can suggest our client's maximum flexibility! Not assembled products such as Grill cabins, Pavilions, Camping pods, and other products of any size you can order painted too!

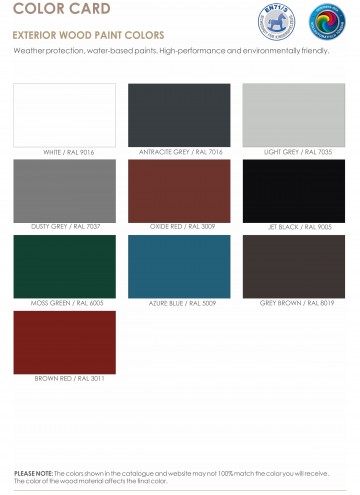

PROFESSIONAL SPRAY

The high-quality preservative finish is professionally spray applied in the factory to three sides of the wood. The product is treated in your choice of color (one color for all product).

STAIN | PAINT

Which type of paint should I Use?

Properly painting and impregnating is one of the most important things to consider when thinking about how to extend your product's lifetime.

Paint and natural wood finish instantly spruce up the aesthetics of your product.

The decision you will need to make is if you want to use a water-based wood stain or paint. Both will offer you UV protection. The wood stains will allow the texture of the

wood to show through and many are now available in a vast range of colors, however, paints will give you an intensive color, but will cover the grain and texture of the wood.

Things to note when using the product:

- Products that are used for staying overnight should be equipped with a smoke alarm and an extinguisher;

- The product owner is responsible for the security and should work out a rescue plan for the camping site;

- Remember that using heating appliances or temporary camping stoves isn‘t just a fire risk, but a risk of carbon monoxide poisoning as well.

MAINTENANCE. You should not forget that wood is a natural material, it changes move depending on weather conditions. Large and small cracks, color tone differences and changes, as well as a changing structure of wood are not errors, but a result of wood growing and a feature of wood as a natural material. Natural wood (not impregnated) becomes greyish after having been left untouched for a while and can be turned blue and become mouldy. You should immediately process them with wood impregnations to protect the wooden details of our produced products.

- Like any our product, our produced furniture’s needs to be looked after and processed with a wood impregnation agent or painted if you want it to last for years. Regular cleaning of your furniture is necessary to prevent mould. General warm soapy water is enough if done regularly;

- If necessary, outside doors must be adjusted by the customer;

- If you do not use your Product often we highly recommend to use the installation of our vent to stop condensation;

- If you find a sap pocket open during the life of your Product - you can allow it to dry naturally and then cut the sap off with a blade.